Save Time & Money

LED Jobsites pay for themselves, and will dramatically reduce downtime, site injuries, and maintenance & installation costs. Substantial labor savings will be realized as LED Jobsite lights require significantly less circuits and are easier to install, move and take down. Adopting the LED Jobsite will pay itself back on the first project and you will further increase your ROI through reusing the lights on multiple projects.

current industry practice

Temporary construction lighting is predominantly still bulb-based, with CFL stringlights, metal halide high bays and quartz halogen flood lights used by most construction sites.

These are outdated technologies that have a lot of drawbacks. Bulb-based lights:

are energy inefficient,

carry safety risks (heat, mercury exposure, broken glass),

generate significant waste

require large material and labour costs to maintain and remove

are typically used for a single job and then thrown out

Temporary lighting is typically bought on price considerations only, creating a 'race to the bottom' of cheap, disposable product.

Typical bulb-based usage

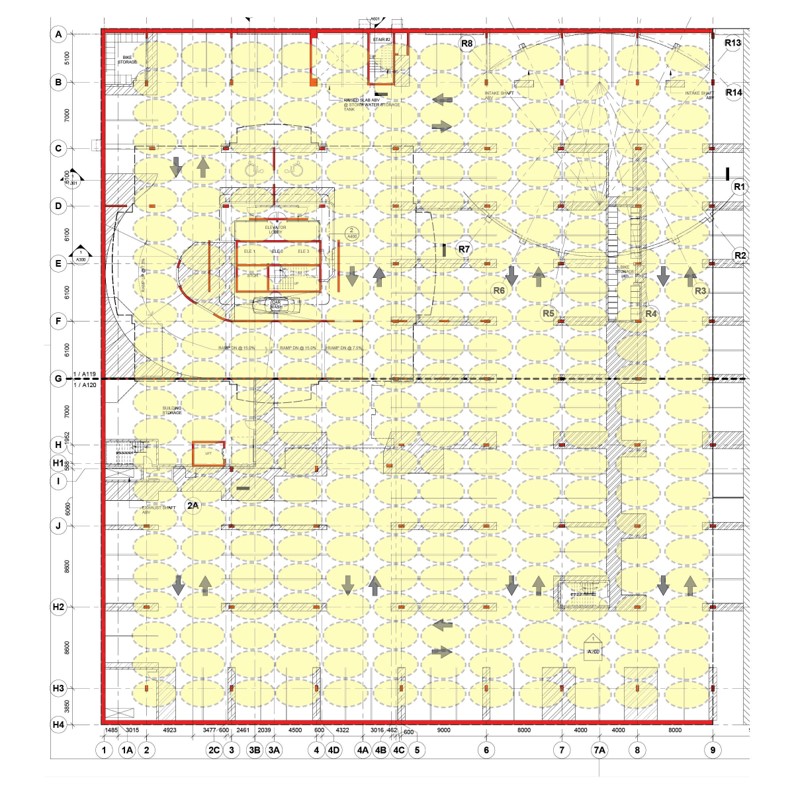

Lighting a jobsite with stringlights is inefficient and requires a lot of labour. Take for example a 50,000 sq ft parkade.

Using bulb-based lighting, this would require 28 x 100' stringlights, costing over $7,300 in electricity every year, and requiring labour to install, maintain and remove 280 individual hanging points.

In addition to these labour and energy costs, bulb-based lights:

have frequent breakage and burnout issues,

are not easily moved or repurposed as the construction progresses,

are not built to withstand weather or impact, and

are typically discarded at the end of a project

Lighting a 50,000 sq ft parkade with bulb-based stringlights requires 280 points of installation (even with using LED bulbs)

Lighting that same parkade with the LED Jobsite system requires only 12 hanging points, dramatically reducing costs.

the led jobsite is the better solution

The LED Jobsite, in comparison, would require only 12 hanging points of bright, efficient and durable LED construction lights to light that same 50,000 sq ft parkade. The LEDs don't need changing like traditional bulbs, and can withstand weather and impact.

In addition to saving a dramatic amount of labour on the install and removal, the LED Jobsite lights can easily be moved around and can run on many fewer circuits. The electricity required to light this area amounts to only $1,600 per year, almost 80% less than bulb-based lights!

LED Jobsite lights can:

be reused again on future projects, furthering the ROI

last for over 5 years of 24/7 use without significant dimming

withstand weather (IP65 weatherproof) and impact (rugged, durable construction)

be installed through a simple plug and play system

be daisy-chained together on fewer circuits, and their triple-outlet daisy-chain allows for complex patterns of lights to be created

be used for an entire project without any maintenance

potentially get your project a LEED credit

See the savings

By purchasing and installing fewer, more energy efficient lights, the LED Jobsite is a less costly option than traditional bulb-based temporary lighting, even on the first project. And when you add in the ability to re-use the LED Jobsite lights again and again on future projects, the ROI is a no-brainer.